WEMOCO - Warfield Electric Motor CompanyWarfield Electric Motor Company, a premier leader among electric motor manufacturers in the USA, specializes in manufacturing custom designed DC electric motors for your application. Whether it is redesigning an existing electric motor or a new prototype Warfield is the best choice.

The custom DC electric motor manufacturing process is fully backed by an in-house machine shop with 5 CNC Machines and Engineering department allowing for prompt customization upon request. Industries include: Renewables, Wind Turbine, Mining, Emergency Siren, Material Handling, Ground Support Equipment, and many more industrial solutions. |

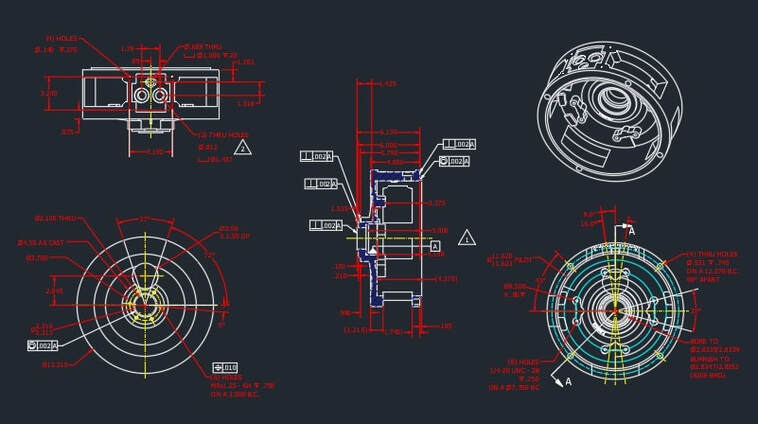

Engineering & Technical Drawing

At Warfield Electric Motor Company, our skilled engineers use state-of-the-art Computer Aided Design (CAD) software to create precise technical drawings of your motor.

Whether you're modifying an existing motor or designing a new one, we work closely with you to understand your specific requirements. Our designs take into account factors like intended application, operating environment, and energy efficiency.

Once the design is finalized, it undergoes rigorous testing and simulations to ensure optimal performance.

Our commitment to precision and quality as a seasoned industrial electric motor company is evident in our meticulous attention to detail during this phase.

In essence, our Engineering and Technical Drawing phase is the beginning of a partnership, where we work together to create the perfect motor for your needs.

Whether you're modifying an existing motor or designing a new one, we work closely with you to understand your specific requirements. Our designs take into account factors like intended application, operating environment, and energy efficiency.

Once the design is finalized, it undergoes rigorous testing and simulations to ensure optimal performance.

Our commitment to precision and quality as a seasoned industrial electric motor company is evident in our meticulous attention to detail during this phase.

In essence, our Engineering and Technical Drawing phase is the beginning of a partnership, where we work together to create the perfect motor for your needs.

Building Process -

|

Setting the standard for quality production among custom electric motor manufacturers, our building process is a meticulously planned sequence of stages, ensuring the production of high-quality electric motors.

We begin with a comprehensive inventory of parts, carefully organized and ready for assembly. Our skilled technicians then assemble each motor, whether new or re-manufactured, with precision and attention to detail, ensuring each component fits perfectly for optimal performance. To reduce lead times and meet your needs promptly, we strategically build motors in advance, ready for immediate shipment upon order. This systematic approach allows us to serve a wide range of industries, from renewables and mining to material handling and ground support equipment, with reliable and efficient electric motors. |

CNC Machine Shop

|

At Wemoco, our CNC machine shop is a critical part of our customization process.

Equipped with five state-of-the-art CNC machines and staffed by skilled machinists, we have the capability to tailor DC Motors to any specific application. From modifying keyway applications to adjusting end heads, our team can make precise alterations with unparalleled accuracy. This level of customization ensures that our motors fit seamlessly into your operations, regardless of the complexity of your requirements. Our CNC Machine Shop is a testament to our commitment to providing bespoke solutions, ensuring that each motor we produce is a perfect fit for its intended application. This capability allows our team at the Warfield Electric Motor Company to deliver motors that meet the highest standards of performance and reliability. |

Dyno Testing -

|

Our commitment to quality extends to rigorous Dyno Testing of all our manufactured motors.

Each motor, whether a standard model or a custom prototype, is load tested on our specially designed dynos. These dynos are versatile, capable of testing all types of motors and generating power curves at various load levels. This allows us to verify that each motor performs to specification under realistic operating conditions. Our setup features two distinct dynos, each designed for specific testing scenarios. The dyno on the left is versatile, capable of load testing a wide range of motors, from the smallest to the largest, in a flexible setting. On the right, our specialized dyno focuses on testing specific load ranges for the 20 NM to 30 NM GE and AMD motors. As the premier choice among wind turbine motor manufacturers, this dual-dyno approach allows us to conduct comprehensive and precise testing for all our motors. Regardless of the application - be it renewables, mining, or industrial solutions - this rigorous testing process guarantees that every motor we deliver meets the highest standards of performance and reliability. |