(something here?)

PRODUCTS

(product will "shuffle" based on which category viewers click on)

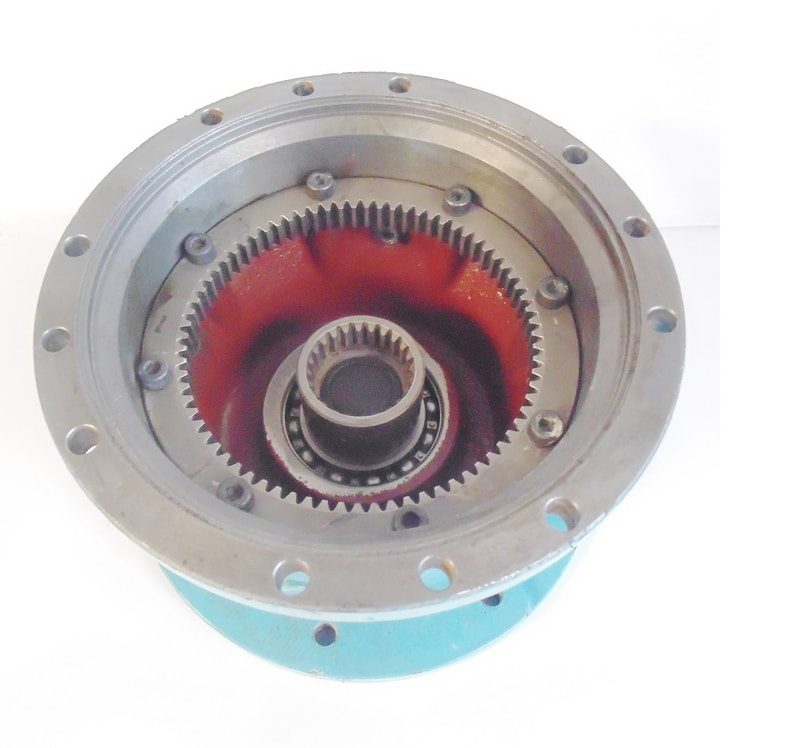

10,0000

PARTS

5,000

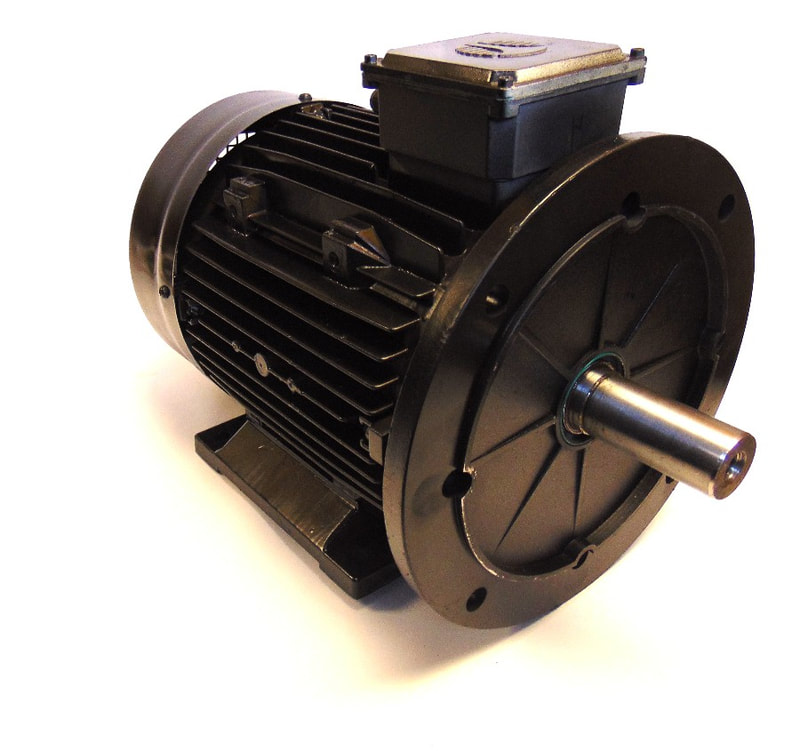

REBUILT MOTORS

150,000

QUESTIONS ANSWERED

500,000

HAPPY CLIENTS

(something here?)

(Quick Contact Form Here?)

(something here?)